Embrace the future:

The EN7000v2D & EN7000v2D-TS Drum Welder

Optional Programming Tools include the WSP3 Held Programmer and NetFlash

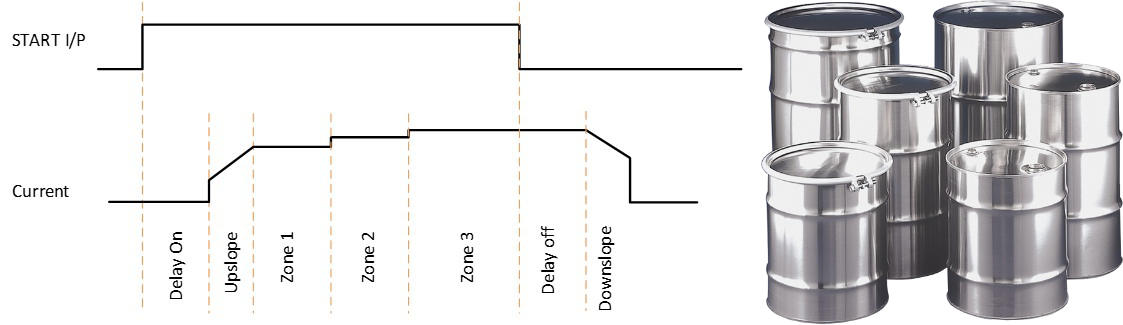

The EN7000v2D Constant Current AC Resistance Welding control has a dedicated drum welding profile. The control features include programmable upslope, 3 heat zones, delay and downslope. This is available in two formats with or without integrated touchscreen. The control comes with ethernet IP as standard and can have up to 256 dedicated weld programs.

The Technology Benefits of the EN7000v2D Drum Welder

- 16 Inputs /16 Outputs (Short Circuit Protected)

- Secondary or Primary Current regulation

- Current Monitoring

- Power Factory Setting

- Configurable 50 / 60 Hz

- Data Log (Drums) 6000

EN7000v2DTS-800A-TC500-EDS

This control is ideal for the steel drum industry. Where low or high speed output is required for manual and fully automatic machines.

MFDC IPAK2v2D Control Variation

Looking for a MDFC Control instead? Then our MFDC iPAK2v2D Control offers many of the same features.

1000 Hz Medium Frequency Control

Control up to 256 weld programs with millisecond precision.

Dedicated Sequence

The control features include programmable upslope, 3 heat zones, delay and downslope.

MFDC Suitable

The iPAK2v2D is designed for MFDC transformers while offering the same programmable features as the EN7000v2D AC control.

Connect With a Technical Specialist

Complete the form to connect and discover how the EN7000v2D & EN7000v2D-TS Drum Welder can revolutionize your welding operations. Achieve welding excellence today.

Connect with us Today

Mexico

Mexico